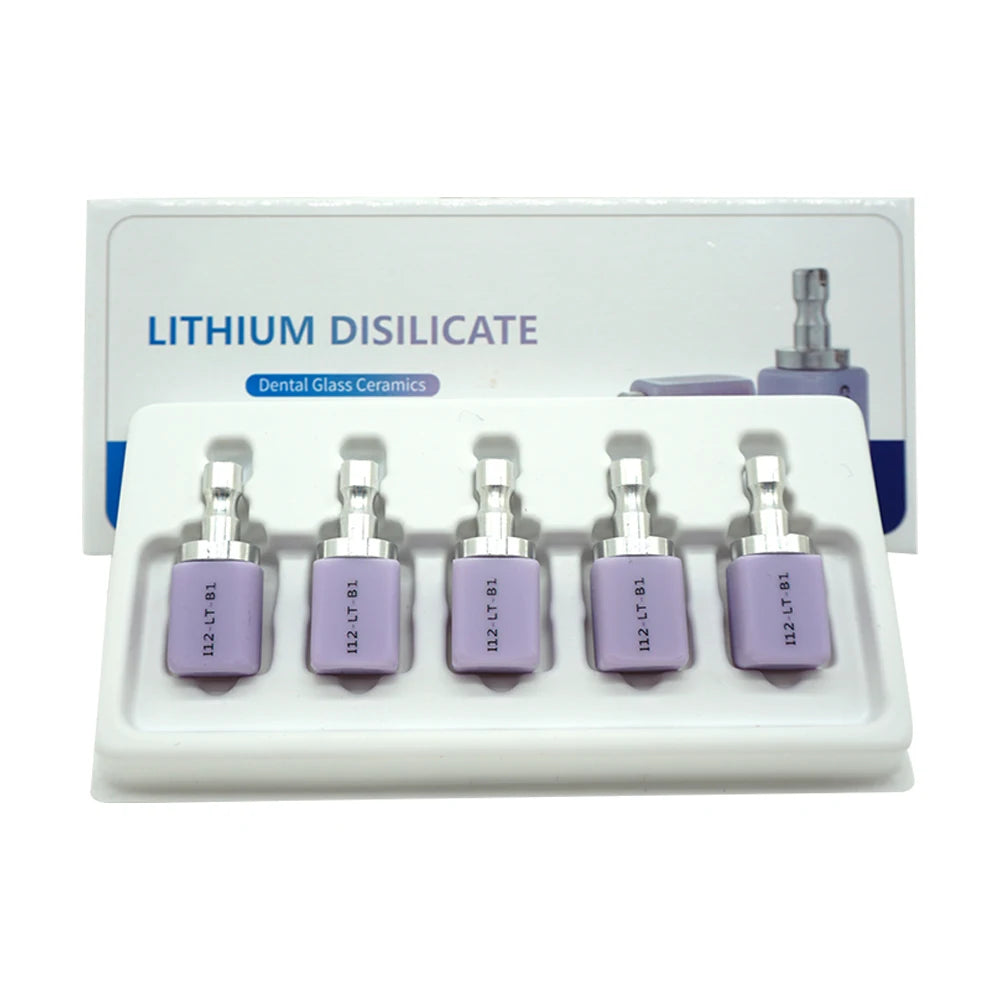

Zirgem Dental Lithium Disilicate I12 50PCS Glass Ceramic Cubes Blocks HT/LT for CAD CAM Dental Crowns Lab Material 98mm

Features:

High aesthetic repair effect

High chemical stability and binging strength

Easy milling,prolong the service life of burs

Simple and rapid crystallization process to reduce operating time

Unique chameleon property guarantees excellent restorative effect

Processing Options For Lithium Disilicate Glass Ceramic Blocks:

Monolithic processing or partial ceramic veneering

Optional brush or dipping infiltration possible

High aesthetic restoration effect

High chemical stability and bending strength

Physical Properties:

Density:2.4-2.6g/cm3

Coeffocoemt of thermal expansion(20-500℃):(8.5-11)10^(-6)k^(-1)

Vickers hardness:≥550HV2

Chenmical solubility after sintering:<100ug/c㎡

Crystallization temperrature:840-850℃

Chemical Composition:

SiO2:61%-75%

P2O5:1%-5%

AI2O3:1%-5%

LI2O:11%-19%

K2O:3%-9%

Other oxides:0%-15%

Size:15.5*13*11mm

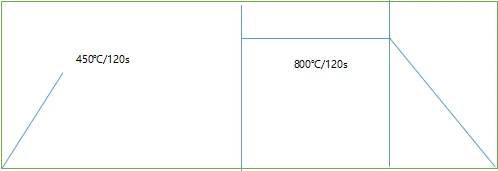

FIRING PARAMETERS & BASIC OPERATION

-Standard-

① Steps

Color comparison → impression → CAD design → grinding for 15~35 minutes (due to the specification difference of the restoration) → glazing or enamel → sintering → inspection → bonding

② Sintering procedure(Take the E.MAX P310 porcelain casting furnace as an example. Different sintering furnaces have temperature deviations and need to be fine-tuned according to the actual situation.)

The processing takes about 25 minutes:

③Start at 450°C, put in the restoration to be sintered, last for 2 minutes, heat up at a rate of 30°C/min, the temperature rise time is about 12minutes (750 seconds), heat up to 850°C and hold for 7minutes (420seconds), then open The cover is directly cooled by air.

④ If you need to glaze a second time, the corresponding glazing procedure:Start at 450°C, put the restoration to be glazed, dry time 2 minutes, heating rate 50°C/min, heating time 7minutes (420seconds), heating to 800°C for 2 minutes (120 seconds), and then directly Adopt air cooling.

Special Note:

There may be a shrinkage rate of no more than 0.2% during the sintering process, which must be fully considered in the design software.

If the glazing and sintering steps are combined, use the procedure ③ to operate. If the sintering and glazing are used in a step-by-step manner, use the procedure ③ for sintering first, and then use the procedure ④ for glazing.

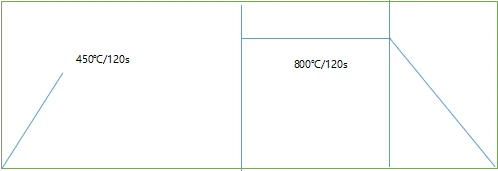

-Veneer Amber Color-

①Steps

Color comparison → impression → CAD design → grinding for 15~35 minutes (due to the specification difference of the restoration) → glazing or enamel → sintering → inspection → bonding

② Sintering procedure(Take the E.MAX P310 porcelain casting furnace as an example. Different sintering furnaces have temperature deviations and need to be fine-tuned according to the actual situation.)

The processing takes about 25 minutes:

③Start at 450°C, put in the restoration to be sintered, last for 2 minutes, heat up at a rate of 30°C/min, the temperature rise time is about 12minutes (750 seconds), heat up to 827°C and hold for 4minutes (240seconds), then open The cover is directly cooled by air.

▲Can be used or not used Object Fix Flow. If you use Object Fix, please select IPS Object Fix Flow.

④ If you need to glaze a second time, the corresponding glazing procedure:Start at 450°C, put the restoration to be glazed, dry time 2 minutes, heating rate 50°C/min, heating time 7minutes (420seconds), heating to 800°C for 2 minutes (120 seconds), and then directly Adopt air cooling.

Special Note:

There may be a shrinkage rate of no more than 0.2% during the sintering process, which must be fully considered in the design software.

If the glazing and sintering steps are combined, use the procedure ③ to operate. If the sintering and glazing are used in a step-by-step manner, use the procedure ③ for sintering first, and then use the procedure ④ for glazing.

WORLDWIDE TRAINING COURSES

Specifications:

Material: Dental Lithium Disilicate I12

Size: 98mm cubes

Color: HT/LT options

Vickers Hardness: ≥550HV2

Chemical Composition: SiO2: 61%-75%, P2O5: 1%-5%, AI2O3: 1%-5%, LI2O: 11%-19%, K2O: 3%-9%, Other oxides: 0%-15%

Sintering Temperature: 840-850℃

Features:

|I12 Ht/lt|

**Advanced Material for Superior Dental Restorations**

The Zirgem Dental Lithium Disilicate I12 is a high-quality glass ceramic material designed for dental professionals seeking durable and aesthetically pleasing restorations. With a Vickers hardness of ≥550HV2, these cubes offer exceptional strength and wear resistance, ensuring long-lasting results for your patients. The material's chemical composition is meticulously balanced to provide optimal flexural strength and fracture resistance, making it an ideal choice for a variety of dental applications.

**Versatile and User-Friendly Processing Options**

The Zirgem Dental Lithium Disilicate I12 blocks are compatible with both monolithic processing and partial ceramic veneering, providing dental technicians with the flexibility to create restorations that meet the unique needs of each patient. Optional brush or dipping infiltration methods are available, allowing for a tailored approach to achieving the desired aesthetic and functional outcome. The ease of milling and prolonged service life of the burs make this material a cost-effective choice for dental laboratories.

**Aesthetic and Functional Excellence**

The glass ceramic material offers a unique chameleon property that ensures an excellent restorative effect, blending seamlessly with natural tooth structure. The HT/LT options provide the versatility to create both highly translucent and opaque restorations, catering to various clinical scenarios. The cubes' physical properties, including a density of 2.4-2.6g/cm3 and a thermal expansion coefficient of (8.5-11)10^(-6)k^(-1), contribute to their exceptional performance and reliability. With the appropriate firing parameters, these blocks can be sintered to perfection, ensuring a high-quality restoration that not only looks natural but also withstands the rigors of daily use.